Roller type compost screening machine for sale

November.22,2019

November.22,2019

Compost screening machine is a energy saving sorting equipment widely used in pre-sorting and composting of urban mineralized waste. The screen cylinder of the roller screen is supported by a roller. During operation, the two active rollers on the side of the cylinder are rotated by a motor, a reducer, etc., and the active roller drives the cylinder to rotate by the frictional force, while the other side The two roller wheels act as slaves. This trommel screen has low energy consumption.

High capacity compost screening machine

How does the compost screen work?

The screen surface is the working part of the compost screening machine and needs to be mounted on the frame and fixed by bolts and pressure plates. The screen body supports a left-right symmetric arrangement, a friction transmission, and a bilateral drive. The screen cylinder is supported on the driving wheel, and the motor rotates through the speed reducer to drive the screen cylinder. The transmission form of the trommel screen is divided into gear transmission, chain transmission, belt transmission and friction transmission according to the screen driving mode.

The inclination angle of the trommel screen affects the residence time of the garbage material in the sieve cylinder. It is generally considered that the inclination angle of the trommel sieve cylinder is within the range. The material to be sieved enters the cylinder from one end of the cylinder into the cylinder. Due to the rotation of the cylinder, the material slides along the inner wall of the cylinder, and the fine material smaller than the sieve mesh hole falls into the receiving tank, and the coarse material larger than the sieve hole is The other end of the cylinder is discharged.

Small type compost roller screen

Machine Structure

The structure of the sieve cylinder has a circular shape, a polygonal shape, and a composite shape. Usually, the circle is used because the balance of the circle is good, the operation is smooth, the processing is simple, and the balance between the polygon and the composite shape is poor, and the vibration of the motion is large. The screen cylinder is mainly composed of a sieve plate, a frame, and a guide plate. The sieve plate is formed by punching or drilling a mesh hole on a certain thickness of the steel plate and determining the thickness of the sieve plate according to the characteristics of the sieved material, the sieve plate needs to meet the requirements of high strength, uniform wear and long service life.

APPLICATIONS

The trommel screen is a widely used machine in sorting technology. It controls the sorting of garbage by the size of the particles, and the sorting accuracy is high. The barrel of the trommel screen is generally divided into several sections, depending on the specific situation, the sieve holes are arranged from small to large, and the sieve holes on each section have the same aperture.

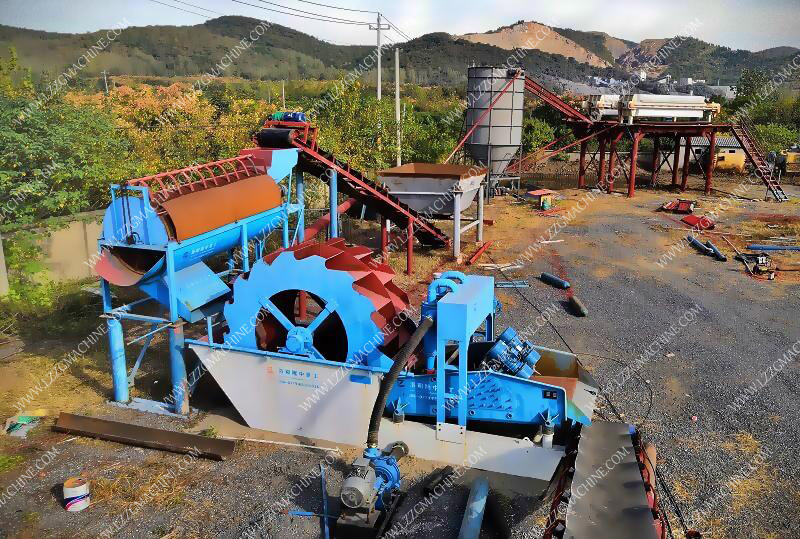

- In the stone quarry, it is used for grading large and small stones and separating soil and stone powder.

- It is used for sand and gravel separation in sand and gravel fields.

- The coal industry is used for the separation of lump coal and pulverized coal and for coal washing (a component of coal washing machinery).

- The chemical industry and mineral processing industry are used for the classification of large and small blocks and the separation of powdery substances.

- Feed screening, compost screening.

Services

Assign special after-sale service team to site guiding customer to install and adjust machines

Training operator on site

During the 1 year warranty period, the product will be faulty due to quality problems, and the damaged parts will be repaired or replaced free of charge by the after-sales department.

Provide technical service support for life.

Contact the manufacturer

Tel: +86-379-65160016 Fax: +86-379-65160018

Email: export@lylzzg.com