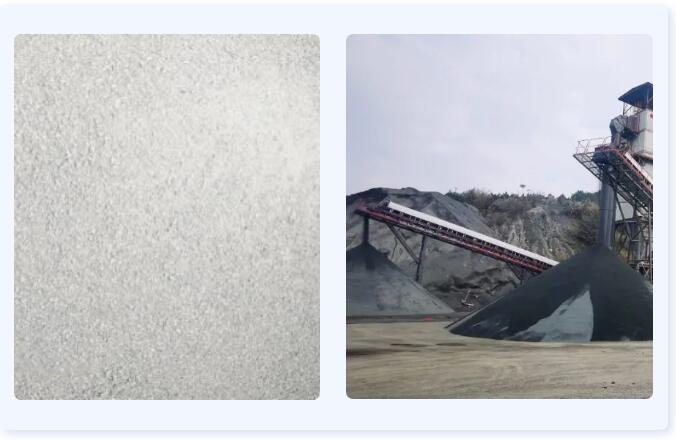

Construction waste crusher for sand making

July.11,2020

July.11,2020

Crusher turns construction waste into sand

The construction waste special crusher has the characteristics of simple operation, energy saving, product shape cube, adjustable discharge particle size, optional crushing, simplified crushing process, and reduced investment. The most common crushing equipment are jaw crusher, hammer crusher, VSI impact crusher.

Construction waste sand making machine is suitable for applications in industries such as hydropower, building materials, highways, and urban construction. It can use construction materials, limestone, granite, river pebbles, concrete, and other materials to manufacture highway surface materials and highway pavements Aggregate for gravel and railway.

Principles of construction waste crusher

As far as jaw crushers are concerned, although the structure types are different, their working principles are basically similar, except that the moving trajectory of the movable jaw is different. In a nutshell, when the movable jaws periodically reciprocate around the suspension axis to the fixed jaws, sometimes approach and sometimes leave, ore between the two jaws when the movable jaws approach the fixed jaws It is broken by the combined action of crushing, splitting and bending and breaking; when the movable jaw plate leaves the fixed jaw plate, the crushed ore is discharged through the ore outlet of the crusher under the action of gravity.

How to buy high-quality jaw crusher

1. Frame design-integral casting vs split assembly

Due to the limitations of casting technology, the overall casting frame will form a large number of tiny pores or inclusions during the casting process, so the overall performance of the frame is reduced. Relatively speaking, the split-assembly rack-type jaw crusher is lighter, stronger and more durable.

2. Jaw plate design-overall vs three-stage

Large jaw crushers mostly use three-stage combined jaw plates. In addition to being more convenient for assembly, installation and disassembly, the main thing is the small one in the middle, the size of the two ends is the same. If the bottom end of the jaw plate is worn seriously, you can The position of the upper jaw is reversed and continued to be used, saving costs.

3. Fixing method of bearing seat-welding vs bolt

Some jaws are broken, and the bearing seat is welded to the frame, and some bearing seats are made of integral cast steel structure and are connected to the frame with bolts to ensure complete cooperation with the crushing frame and greatly enhance the radial direction of the bearing seat. strength. Different manufacturing processes make the service life of the two different.

In addition, some jaws are broken and heavy protective plates are installed on their bearing seats to avoid accidental damage to the bearing seats.