Frac sand washing plant oil fracturing proppant processing equipment

April.13,2020

April.13,2020

Use of frac sand

Fractured sand is high-purity quartz sand, with super strong pressure resistance and extremely high roundness. It is made of natural quartz sand through multiple processes and fine processing, and is used in the petroleum industry. Especially in the application of hydraulic fracturing, that is, the high-pressure water pump is used to inject fracturing fluid into the oil and gas reservoir, and the reservoir is crushed to obtain oil and gas resources. Fracturing quartz sand is an indispensable substance. Part of the fracturing quartz sand comes from high-purity quartz sandstone, which is processed through multiple processes such as crushing.

The petroleum proppant enters the formation along with the high-pressure solution to fill the rock fissures, and plays the role of supporting the fissures not to be closed due to stress release, thereby maintaining high conductivity, making the oil and gas smooth, and increasing production.

screw frac sand washing screening machine

This frac sand production line include stone crusher, screw sand washer, sludge thickener, filter press, blet conveyor, VSI sand making machine.

Its production process

raw ore → pre-selection and screening → scrubbing → desliming → coarse particle classification → fine particle classification → magnetic separation → concentration → dehydration screen → dryer → screening → finished product. It has ultra-high pressure resistance and extremely High roundness. Currently, quartz sand accounts for 50% of the market share.

Frac sand project has annual production capacity of 400,000 tons of oil and gas. The total investment of the project is 100 million yuan, and the designed annual production capacity is 400,000 tons.

silica frac sand washing plant

The fracturing sand is subjected to soft hydraulic friction cleaning and fine sieving to produce a fracturing sand proppant that meets the needs of oilfield fracturing production, which meets the needs of the unconventional oil and gas exploitation of Mahu Oilfield in Buxel County.

The performance requirements of petroleum proppant

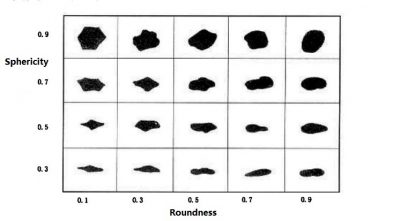

1. The proppant must have sufficient compressive strength and wear resistance, can withstand the strong pressure and friction during injection, and effectively support artificial cracks. 2. The relative density of proppant particles should be low to facilitate pumping downhole. 3. The proppant particles do not chemically interact with the fracturing fluid and reservoir fluid at a temperature of 200 degrees. The maximum allowable value of acid solubility should be less than 7%.

At present, the commonly used proppants mainly include quartz sand, bauxite ceramsite sand and resin-coated composite particles. Because quartz sand has low cost and low density, it is easy to pump and is widely used. However, quartz sand has a low strength bottom and poor sphericity, which reduces fracture conductivity and is not suitable for deep wells with high closed pressure.