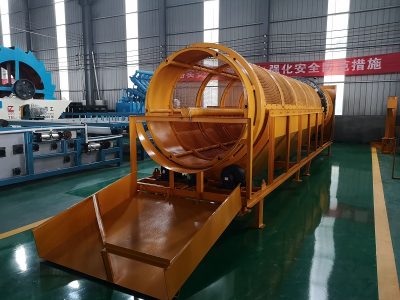

Lump coal and pulverized coal rotary drum separator

April.21,2020

April.21,2020

Lump coal screening rotary drum separator is widely used in the sorting of various minerals, ores, coal blocks, such as potash feldspar, kaolin ore, limestone. Coal mine.

The roller device is installed on the rack at an angle. The motor is connected to the roller device via a reducer through a coupling and drives the roller device to rotate around its axis. When the material enters the roller device, due to the inclination and rotation of the roller device, the material on the screen surface is turned and rolled, so that the qualified material (the product under the screen) is discharged through the outlet at the bottom of the rear end of the roller, and the unqualified material (screen Upper product) is discharged through the discharge port at the rear of the drum.

Due to the turning and rolling of the materials in the drum, the materials stuck in the screen holes can be ejected to prevent the screen holes from being blocked.

Rotary coal separator

Screening of wet and dry materials

For dry material, trommel screen is turned over to make the material and the screen effectively contact, and the dry material can be quickly screened.

For wet material, the machine drives the wet material to roll so that the materials are thoroughly mixed with the air. Making them drier, facilitating screening and reducing the blockage of the screen.

Advantages of LZZG rotary drum coal separator

The design of the drum screen is mostly an integral welded structure. The welded drum screen is especially a large drum screen (the inner diameter of the screen drum is 2.4m, the maximum outer diameter of the rolling ring and transmission parts is 2.8m, and the length of the drum is 12m). Reliable benchmarks, and there are welding deformations during the assembly welding process. It is very difficult to ensure the coaxiality between the roller ring and the roller ring, the roller ring and the transmission part, and the manufacturing accuracy is unstable.

After improvement, the drum screen was split into several small units, and the large-scale welded structural parts became small unit structural parts, making the structural parts less difficult to manufacture. After processing, the units are assembled together, and the structure of the roller screen is changed from welded structural parts to mechanically processed fittings. The production accuracy is guaranteed by mechanical processing methods; the product quality is stable. The improved equipment is more widely used, and the application of drum screens in the coal industry is also more efficient.