Quartz sand 99.9% purification process

January.15,2024

January.15,2024

With the extensive use of quartz resources, high-quality crystal and vein quartz are decreasing day by day, and low-grade quartz resources are receiving more and more attention. LZZG has developed natural quartz sand and quartz sandstone purification processes for customers.

High-purity quartz sand refers to quartz sand with a silica content higher than 99.9% (3N). Low-end, mid-range and high-end products are distinguished by silica content of 99.9%, 99.99% and 99.998%.

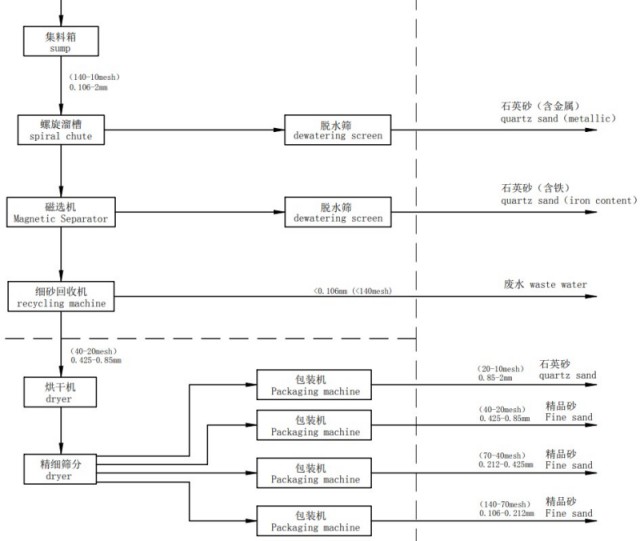

Quartz sand purification and dry classification process

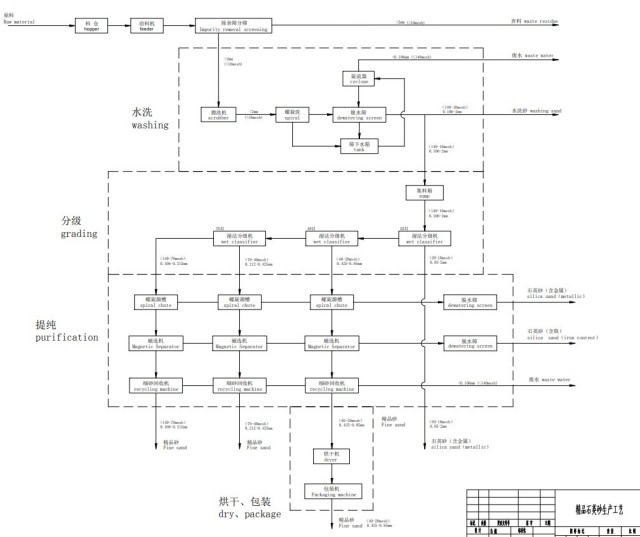

Natural quartz sand enters the collecting box after being washed with water, and is classified into different specifications by a spiral chute and a magnetic separator. After purification, it is classified into different specifications by a vibrating screen or hydraulic classification machine.

Quartz sand purification and wet classification process

The main raw materials for high-purity quartz sand are quartz ore, natural crystal, and silicon tetrachloride. High-purity quartz sand can be used in photovoltaic, electric light sources, optical communications, semiconductor and other industries by preparing intermediate products such as quartz crucibles and quartz sleeves. , is an important new material.

Quartz materials for semiconductors have the highest quality requirements, with purity requirements above 5N (>99.999%), followed by photovoltaics and optical communications, with quality requirements above 4N7 (>99.997%), and light source fields with quality requirements >99.99%.