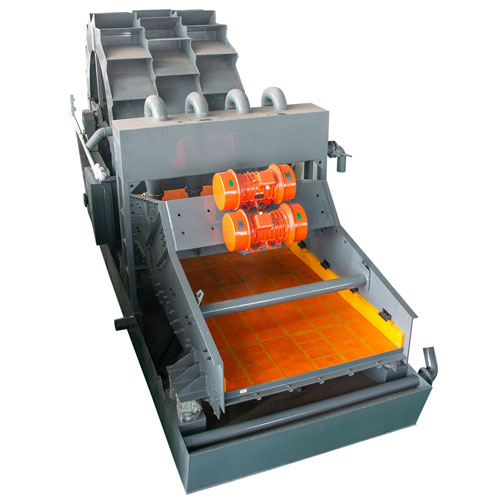

20 tons per hour sand washing and screening machine

April.19,2022

April.19,2022

The ore washing and screening integrated machine combines the wheel sand washing machine and the dewatering screen into one machine, which has the functions of cleaning and dewatering, and the whole machine is integrated, which is easy to move. This type of body machine has a compact structure, which solves the problem of high mud content and high water content in the finished sand in the actual sand washing of the sand field and tailings.

Advantages of washing and screening integrated machine

1. The integrated ore washing and screening machine combines the advantages and characteristics of the sand washing machine and the dewatering screen.

2. The mud, water, dust, impurities, etc. in the sand are greatly reduced, and the quality and price of the sand are improved.

3. Energy saving and environmental protection, low energy consumption.

4. The whole machine is installed, and the transportation is convenient and fast.

5. Low failure rate and long service life.

6. Large output and high efficiency.

Maintenance of Ore Washing and Screening Integrated Machine

1. Before starting the ore washing and screening integrated machine, rotate the rotor by hand to check whether there is any abnormal phenomenon in each part of the machine.

2. Always check the oil level of the reducer, the tightness of the belt, the meshing degree of the gears and the lubrication condition, and whether the connecting fasteners are loose, and ensure that the machine is in a normal and stable working state. At the same time, the friction parts should be fully lubricated and greased regularly.

3. After adding lubricating oil to the reducer for one month, the lubricating oil should be replaced in time, and filtering should be carried out when filling. The type of lubricating oil should be selected in low-latitude areas than in high-latitude areas. Higher viscosity lubricating oil.