Tailings disposal dewatering equipment

August.17,2019

August.17,2019

Tailings treatment is an important part of mine production and an important part of the construction and operation of the ore dressing plant. In recent years, due to environmental and safety pressures, many problems exist in the traditional tailings surface storage methods, Develop safe and efficient tailings treatment technology.

Introduction to high-efficiency gravity sedimentation dewatering equipment

High-efficiency gravity sedimentation dewatering equipment uses flocculant to assist dehydration and increase the concentration of concentrated products. Representative new gravity dewatering equipment mainly includes PPSM type thickener and deep cone thickener.

Features:

1 The flocculant is used to increase the particle size of the particles and increase the sedimentation speed.

2. Strictly control the height of the concentrated layer of the deep cone concentrator to improve the concentration effect.

3. Automatic control of working conditions.

When the deep cone concentrator concentrates the metal mine tailings, the tailings concentration can reach 40%~70%, and the suspended matter content in the overflow is small.

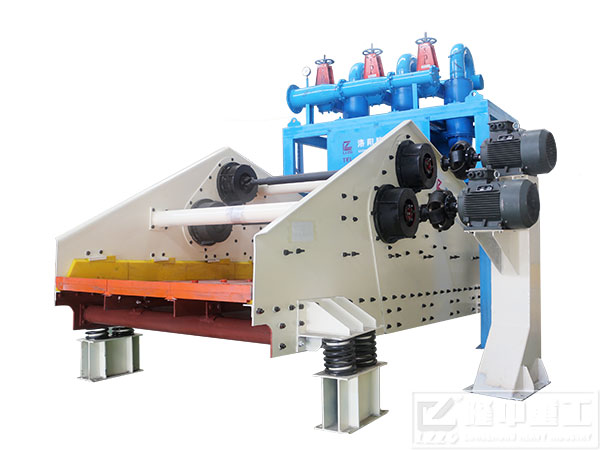

Tailings filter press

The filter press is mainly used for the dehydration of chemical products with fine viscosity, fine particles and concentrates of the ore dressing, gold cyanide washing. The filter press plays an important role in the treatment of gold hydrogenated tailings.

Advantage

Filter biscuit storage, no need to build a tailings dam

Greatly reduced the loss of dissolved gold in the tailings.

No need to buy sand and sand, sea sand to supplement the aggregate.

The high waste water content of tailings is one of the main areas of concerning for the mining industry now, and mine operators are increasingly adopting all kinds of tailings disposal methods to minimise the impact of the tailings on the environment.