Relationship between the vibrating screen material thickness and mesh size

June.12,2019

June.12,2019

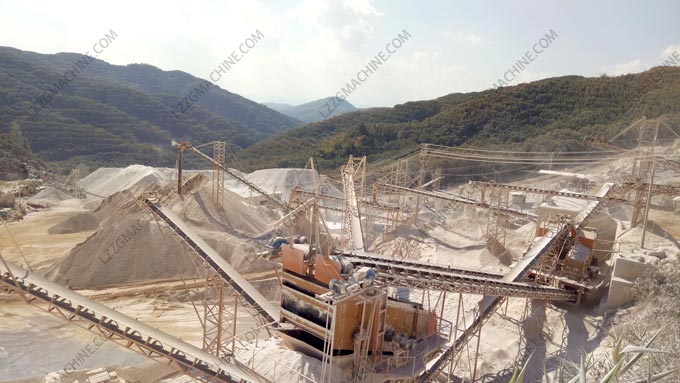

Sand washing plants, coal preparation plants, and mine screening plants will generally apply screening operations to their production lines, and the most used screening equipment such as dewatering, de-intermediation, and desliming. Lzzg develops large-scale and heavy-duty screening equipment expands the screening machinery area, enhances the mechanical vibration intensity of screening machinery, improves the production capacity and load-bearing capacity per unit area of screening machinery, and makes the screening machinery work more reliably and stably to adapt to different industries. Sub-machine requirements.

The screening equipment of Longding Environmental Protection Technology has dewatering sieve, circular motion vibrating screen, thick sieve, high-frequency sieve, relaxation sieve, horizontal sieve, inclined sieve, probability sieve, linear motion vibrating screen, tailings dry sieve and so on.

The general screening process is divided into two types. The first stage: the materials are layered according to the size of the particles. Due to the continuous movement of the screen surface, the material of the screen surface is first loosened and separated (and layered by particle size), the large particle material is continuously raised in the motion, and the small particle material is passed between the coarse particles. The gap, which is constantly falling, is close to the screen surface. The second stage: fine-grained sieve. The fine particles reaching the sieve surface are compared by size through the sieve holes, and the materials smaller than the sieve holes are passed through the sieve holes to enter the sieve to realize the separation of the coarse and fine particles, and the screening process is completed.

In order to achieve the above two stages, the screen surface should have appropriate motion characteristics, which can make the material layer on the screen surface loose, and promote the coarse particles blocked on the sieve hole to be separated from the sieve hole to ensure the fine grain is permeable. The ease of screening through fine particles smaller than the mesh size is different. Compared with the sieve hole, the smaller the particle, the easier it is to pass through the sieve, and the particle size similar to the mesh size is more difficult to screen. During the screening process, the customer always wants the material particles to be graded strictly according to the size of the mesh, and all the particles of the small rain screen size can be sieved out. However, this is not the case. Due to various factors, there are always some fine-grained materials with a small rain screen size left on the screen surface. The more the fine-grained content in the sieve, the worse the screening effect. To solve this problem, we can purchase multi-layer sieves for multi-stage multi-layer screening. Or use different screening equipment to avoid such problems.

The correct way to improve the efficiency of dewatering screen

The thickness of the layer varies depending on the size of the mesh. Generally, the thickness of the layer is not more than 4 times the size of the mesh. Good operating conditions are an important guarantee for improving the production capacity of the sieve and the efficiency of the screening. In the production, the feeding should be ensured to be continuous and uniform, so that the material is covered into a thin layer along the entire width of the sieve surface, which can fully utilize the sieve surface and facilitate the screening of fine particles; in addition, the feeding amount must be less than the rated load of the sieve, otherwise, although The production capacity of the sieve is improved, but the screening efficiency is reduced; even if it is cleaned and repaired during production, it is beneficial to the smooth progress of the screening process without affecting the profit. If you want to know more screening equipment, you can contact online customer service. We will get in touch with you as soon as possible.